#7: How Can 17,000 Tons of Tomatoes Come From Two Ingredients — Sun and Seawater?

In 2016, a little-reported plant opening took place in the desert of South Australia, one that has the power to reimagine the way we produce fresh food in harsh environments.

PRESSED FOR TIME?

We think about solar power and tend to imagine a large footprint of photovoltaic panels through a lonely valley: but for the last five years, 15% of all of Australia’s tomato demand has been met by just one desert facility, with a different type of solar technology. To understand how this story happened, we need to reflect on the power of ideas, financing and existing technologies coming together in unconventional ways.

SOLAR FARMS? NO, SOLAR TOWERS

Technology has a way of creeping up on us. We can develop a fixed image in our mind, and then to great surprise, learn the state of the art is something very different.

The below image is a typical solar farm. A solar farm is a large collection of photovoltaic (PV) solar panels that absorb energy from the sun, convert it into electricity and send that electricity to the power grid for distribution and consumption by customers like you.

Solar farms perform an increasingly critical role in our energy mix. Investment tax credits, rapidly dropping prices, and rising demand for renewable energy are expected to drive the solar energy market globally to $223.3 billion by 2026. In short, it’s here to stay.

The image below is showing something different: it’s a solar tower.

This setup includes an array of large, sun-tracking mirrors known as heliostats that focus sunlight on a receiver at the top of a tower. That’s right, the sunlight is being reflected back to a single spot.

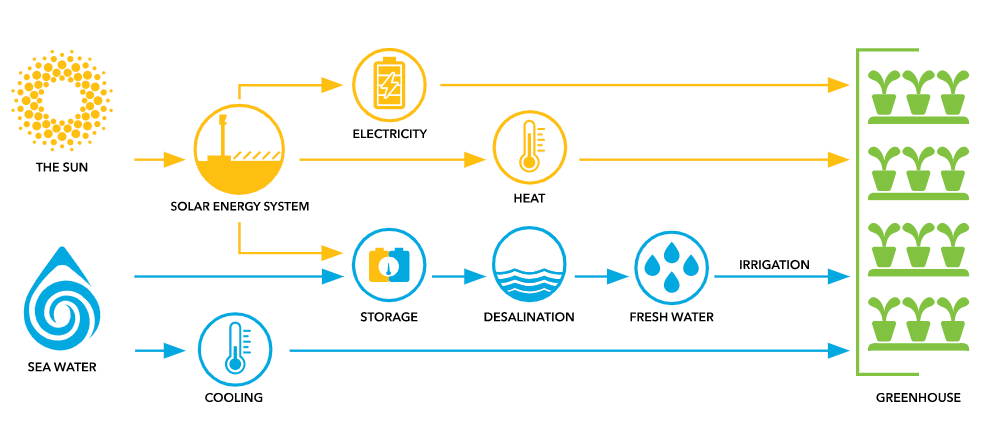

In this receiver, a fluid is heated and used to generate steam. This steam then powers a conventional turbine generator to generate electricity. In this example, the intense heat is used to desalinate water from a nearby ocean source. The desalinated water is then used for agriculture, and the electricity is used to heat the greenhouse where the food grows.

Where did this happen? Port Augusta, South Australia: a former coal town 300km north of the capital city, Adelaide.

SUNDROP FARMS, AUSTRALIA

Through the early 2010s, a small firm called Sundrop Farms came to Australia and spent several years developing this idea at a pilot plant on the outskirts of Port Augusta, before building a commercial facility 100 times larger in 2016. The 20-hectare futuristic-looking facility includes a field of more than 23,000 mirrors that capture the sunlight and direct it to the central receiver (top right) at the top of a 127-metre "power" tower.

All the water used for irrigating the crops is piped from the Spencer Gulf (i.e. the Southern Ocean) and converted into fresh water using a thermal desalination unit. This integrated energy system was the first of its kind anywhere in the world in 2016 — an industry scale concentrated solar power technology used to deliver greenhouse food. The production output? 17,000 tons of truss tomatoes each year.

In 2019, and after a year-long negotiation process, Sundrop Farms was bought by trans-Tasman infrastructure investment firm, Morrison and Co. for an undisclosed amount. The Port Augusta facility now employs over 300 people, and is soon to be joined by Aurora, a much larger solar tower project based on a format in Nevada (below), where mirrors focus the heat of the sun on to the tower containing molten salt. That salt can store the heat for days, if necessary, with minimal loss. When electricity is needed, the salt is circulated through a system where it produces steam, which drives a turbine.

There are no greenhouses filled with tomatoes at the end of this system, simply thousands of homes with renewable power — the Aurora solar power plant will produce 500GWh of electricity a year. This molten salt method addresses the biggest criticism of renewable energy; that when the sun isn’t shining, or the wind isn’t blowing, it isn’t working. During the day, molten salt will flow through the receiver and be heated to temperatures as high as 566°C, then stored in tanks overnight. The energy will be dispatched as electricity when needed — after dark in the evening peaks, or in the morning, hours after it was generated. It will be enough energy to power 90,000 homes, or 5% of South Australia’s total power demand.

Sundrop Farms and its tomato greenhouses were the start of a revolution. Thirteen renewable energy projects are underway or under consideration in Port Augusta. But Sundrop Farms went first, and have hit on something special. But what did it cost, why did all this happen in such a remote location, and what can we learn for other climate investment domains?

RUNNING THE NUMBERS

The Sundrop project cost $200m, with private equity investor KKR providing $100m of the funds to see it through to development. The greenhouses also produce more than 450,000 cubic metres of excess freshwater per year — equivalent to 180 Olympic size swimming pools. At its peak the facility produces 39MW of thermal energy for use as electricity, heating and producing desalinated water, and only needs to draw from the conventional energy grid in rare periods of the year where cloudy and near-freezing conditions combine. In a 50-acre greenhouse project, at any given time the site is carrying about $50-$60 million worth of crop. That’s a lot of inventory at risk.

So how did the project become viable? Australia’s largest grocery retailer Coles (ASX: COL) agreed to exclusive purchase of the truss tomatoes produced via an off-take agreement.

WAIT, WHAT’S AN OFF-TAKE AGREEMENT?

An off-take agreement is an arrangement between a producer and a buyer to purchase or sell portions of the producer's yet-to-be-manufactured goods. It is typically negotiated far in advance, often before construction of the manufacturing facility and actual production has begun. In this case, the producer (Sundrop Farms) found it easier to obtain financing, and the buyer (the grocery mega-chain Coles) secured 17,000 tons of tomatoes annually in its supply chain, at a price that gives them a lot of security, and during windows of the year where tomato demand is stable but other suppliers can’t deliver as much. The overall winner? The Australian customer, who sees more stable tomato prices year-round.

Why is the off-take agreement so important? Because agreements like this are most common in natural resource development, where the capital costs to extract resources are significant and the company wants a guarantee some of its product will be sold.

When it comes to hybrid models that deliver renewable energy and/or food security, we’d be better off using a mental model that makes a tomato feel like silver or gold.

SO WHY PORT AUGUSTA?

Port Augusta is remote, even for Australian standards.

In a country drenched in sunlight, it is particularly abundant in the arid landscape around Port Augusta (320 sunshine days per year). Critically, there are also plenty of flat expanses on which to build the facilities needed to exploit it.

But it isn’t just topography on Port Augusta’s side. The head of the Spencer Gulf is where large thermal winds are generated by increasing temperature differences between land and sea throughout the day. Spanish solar giant Iberdrola recently invested $500m in a 320MW renewable energy park in Port Augusta as well, and put it well in their press release: ‘When combined with the mid-day solar generation, this [location] results in a generation output better matched to the South Australian electricity demand profile when compared to a weather system driven wind or solar only project.’

Plain English: it’s not just sun and flat land, it’s timing. It is sun, flat land, a nearby mountain range and a windy funnel from the ocean that enables renewable energy to be generated at the same times that people use it. What better place to cluster multiple renewable resources?

There is a lot to play out in the 2020s. Commercial financing stalled some projects, but as the demand for renewables rises, these will become increasingly viable. For now, it’s worth considering three key lessons from the Sundrop Farms and Port Augusta story:

THREE LESSONS

1. Sundrop is not pure play agriculture, or pure play renewables, or infrastructure, or water: it’s (sun + seawater) = (energy + greenhouse tomatoes). One of the difficulties the firm had during fundraising was finding partners adept at assessing good levels of risk across all those engineering challenges. When renewable energy projects couldn’t get funded anywhere in Australia in 2014, KKR stepped in. When the venture needed demand, Coles agreed to a decade’s worth of tomatoes (likely for their own carbon footprint goals, of course). Faith was key. It’s worth asking: how many investors would’ve turned them down, and how many similarly brave ideas are stonewalled for the same reason? This is an important question for those investing in climate technology in the next ten years. Can you protect yourselves from downside risk, and what can creative contracts from other sectors do to give confidence?

2. Port Augusta has year-round sunshine, strong winds from the mountain range and Southern Ocean, rail supply lines from old coal station networks, and a nearby disused car factory that can make heliostat mirrors instead of car windshields. It looks the end of the world on a map, but reimagine the world like a renewable energy Monopoly board, and it is Park Lane. This is a great test of our mental models: can we see places around us in a new light? When we evaluate green energy stocks or projects in our region, are we able to see the big picture and the arrangement of future unmet needs?

3. No renewable source is perfect. Near the centre of the Sundrop array temperatures can reach 550°C, and there is evidence that such large area solar concentrating installations can kill birds that fly over them. Again we return to the question of costs and tradeoffs: how do we compare bird casualties to the hyper-efficient spatial footprint of greenhouse horticulture, with a fraction of the land usage and fertiliser? There are not always win-win solutions, hard choices need to be made.

We will return to solar technology in future issues, but for now it’s nice to cover a good news story in the climate world — the burgeoning vines of twenty foot tomato stems, growing thick and juicy under the harsh desert sun, and knowing this might be the first foray into a process replicated in countless inhospitable locations in the years and decades to come.

Optimistically,

Owen C. Woolcock

3 Questions I Am Asking Myself This Week

1. How much of Biden’s $4 trillion infrastructure plan will be the Green New Deal under another name?

2. Seawater next to solar to greenhouses feels so simple once I learned about it, it made think: great ideas look effortless. But because the ideas are so clear, casual observers probably don't appreciate how much time it took to refine them.

3. The cherry blossoms are peaking now in Kyoto. The data record for this annual ritual is a national treasure, having been maintained by emperors, aristocrats, governors and monks over the centuries. Records indicate this spring peak is the earliest in more than 1,200 years, a depressing vignette of our changing climate.

If You Read Or Listen To One Thing This Week

ABC Lateline: Sundrop Farms — if the story of Sundrop interests you, and you’re more of the visual type, this is a news story on the development site from 2016.